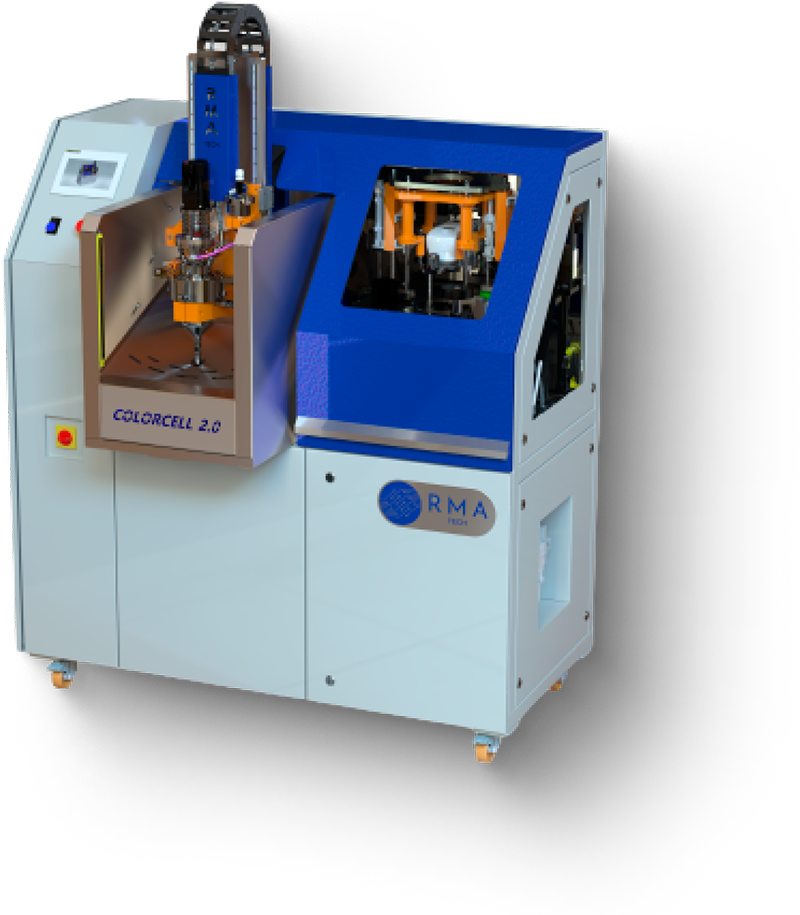

COLORCELL was designed to quickly and precisely measure and adjust one of the most complex properties of the Paint Industry; Color.

We provide both a Lab-Version and an In-Line Version, intended to facilitate process manufacturing automation, leading to reduced production cycle and enhaced product quality.

EXCLUSIVE

COLORCELL is an exclusive process automation cell from RMA TECH, with effective operational results for over 30 years.

PRECISION

It uses a wet color measurement technique, renowned for its precision.

AUTOMATION

It is integrated into manufacturing processes, automating paint production.

COST REDUCTION

COLORCELL enables reduction in saturation (coverage) and so minimizes costs in the pigmentation package.

INCREASED QUALITY

It guarantees the quality of a color, which can lead to greater customer satisfaction.

COLORCELL uses a wet color measurement technique that allows the measuring of the paint’s color without the need for wasting time on drying (traditional method).

This technology is integrated with other control systems, such as ERPs and corporate systems. This enables real-time data flow and more effective decision making.

The In-Line Version of COLORCELL uses artificial intelligence features that reduce paint waste while improving the paint’s quality.

It can be included in manufacturing processes, automating color measurement. This reduces manual labor, increases efficiency and improves safety.

COLOR MEASUREMENT

COLORCELL’s Technology

A color measurement method conducted using a wet (liquid) basis, facilitating fast and precise measurement for solid colors, suitable for seamless integration into manufacturing processes.

TRADITIONAL METHOD

A time consuming method involving application steps, drying, and an adjustment cycle that can span days.

VARIABILITY

COLORCELL’s Technology

Nível SIGMA com índice 6 vezes superior à técnica convencional pois realiza a medida direta na amostra sem necessidade das etapas de condicionamento e secagem.

TRADITIONAL METHOD

High variability due to the testing routine itself, resulting in a low R&R and this leads to potential false negatives and positives.

Using a wet color measurement method, it enables the evaluation of paint color without requiring drying, ensuring a more accurate and reproducible measurement. The system includes a continuous flow cell, a spectrophotometer, and a control software. The continuous flow cell maintains paint homogeneity during measurement, and the spectrophotometer accurately measures the paint color. The control software processes measurements and adjusts the paint color as needed.

COLORCELL stands out for its versatility, making it a valuable asset in the paint industry for applications ranging from solid paint manufacturing to metallic and special coatings.

Streamlining color measurement, COLORCELL ensures a seamless and rapid process through its exclusive technology. Its efficiency and flexibility are dedicated to amplifying productivity gains, while simultaneously automating the paint manufacturing process.

COLORCELL´s analytical capacity can be enhanced by incorporating additional features such as Mass Flow Sensor (Density and Viscosity), pH measurement, conductivity, Tinting Strength, coverage analysis, Color Position, etc.