Home / EN / Equipments / SMART DISPENSING MACHINE

SMART DISPENSING MACHINE

A new paradigm of precision and dosing.

SMART DISPENSING MACHINE

A new paradigm of precision and dosing.

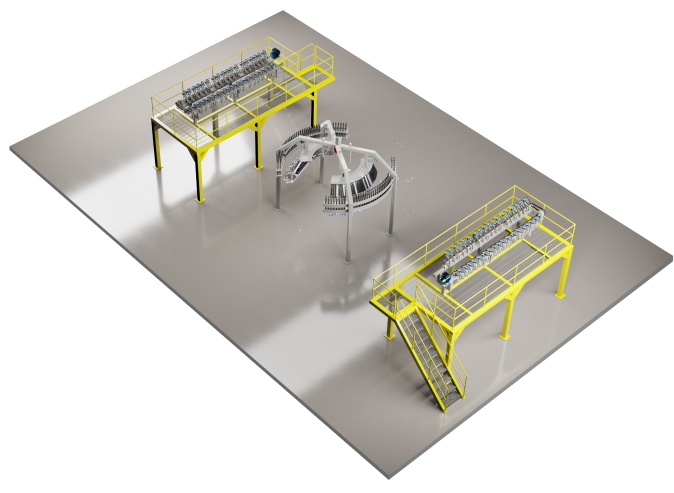

The SMART DISPENSING MACHINE is an innovative solution that offers high productivity, automation, cost reduction, and precision.

Sustainable and Productive Automation

Benefits of the Smart Dispensing Machine.

High Productivity

Highly productive and efficient volumetric dosing system, with the precision and reproducibility of advanced gravimetric dosing systems.

Automation

A 100% system for dosing pump calibration, achievable outside of production hours, pre-programmed, and without the need for the presence of operators.

Exclusivity

The first industrial dispenser on the market with a patented system for individual self-calibration of dosing pumps, 100% automated and operator-free.

Cost Reduction

Through a single transmission shaft and motor, it controls all pumps simultaneously and reduces implementation costs.

It is the first industrial dispenser on the market with a patented system for individual self-calibration of dosing pumps, 100% automated and operator-free.

This exclusive technology ensures the precision and reliability of the system, even under adverse conditions.

A NEW CONCEPT

RMA TECH introduces a pioneering advancement in the industrial dispensing machine market.

Our patented equipment stands out with an advanced and 100% automated “on-line” calibration system. This unique system allows for quick and precise calibrations for each dosing pump, even during idle periods of the machine.

5 Concepts of the Smart Dispensing Machine

1. In-line Calibration System

The RMA SMART DISPENSING MACHINE innovates with an efficient in-line calibration system, utilizing “IN-LINE PROVERS” for individual or simultaneous calibrations of multiple dosing pumps. This method accelerates the dosing system calibration and facilitates predictive maintenance. Manufactured from durable stainless steel, the provers are easily assembled, optimizing maintenance and extending pump lifespan.

2. Dosing Pump Station

This technology stands out with a revolutionary design, utilizing a single motor to drive up to 40 dosing pumps. This innovative system ensures precise volumetric dosing and eliminates the risk of slippage, providing total control over the pumps. It’s its unique approach that makes the machine more competitive and effective, ideal for dosing various components.

3. RMA Profile Smart Dispensing

RMA TECH’s SMART DISPENSING MACHINE features a strategy of simultaneous and smooth dosing, minimizing errors and ensuring precision. With a reduced vacuum system, the machine ensures performance comparable to proportional action valves of high-precision gravimetric dosing machines, improving dosing process efficiency and reliability.

4. Vision System

Incorporates an advanced vision system for dosing monitoring. It utilizes high-resolution cameras and digital image processing to simplify installation and reduce the need for additional sensors. Thus, it allows monitoring and recording of the entire loading process, providing traceability and detailed analysis of dosing valve performance.

5. Dosing Compensation

Enhancing dosing precision, RMA TECH’s SMART DISPENSING MACHINE includes an automatic temperature compensation system for each component. Its temperature sensors, density data, and expansion coefficients automatically adjust material loading according to temperature, minimizing errors and ensuring extremely precise dosing.

ADVANCED TECHNOLOGY

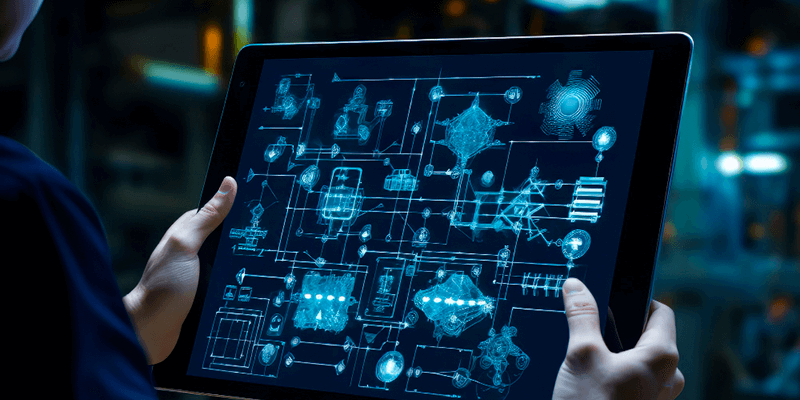

Enabling the Smart Dispensing Machine in Industry 4.0

1. Dosing Capability

Capable of handling up to 100 components for diverse product lines (such as cleaning agents, bases, solvents, additives, etc.).

2. Seamless Integration

Aligns perfectly with RMA TECH’s cost-effective continuous painting concept, synergizing seamlessly with TRANSMICELL base and color analyzer/qualifier.

3. Complete Integration

v