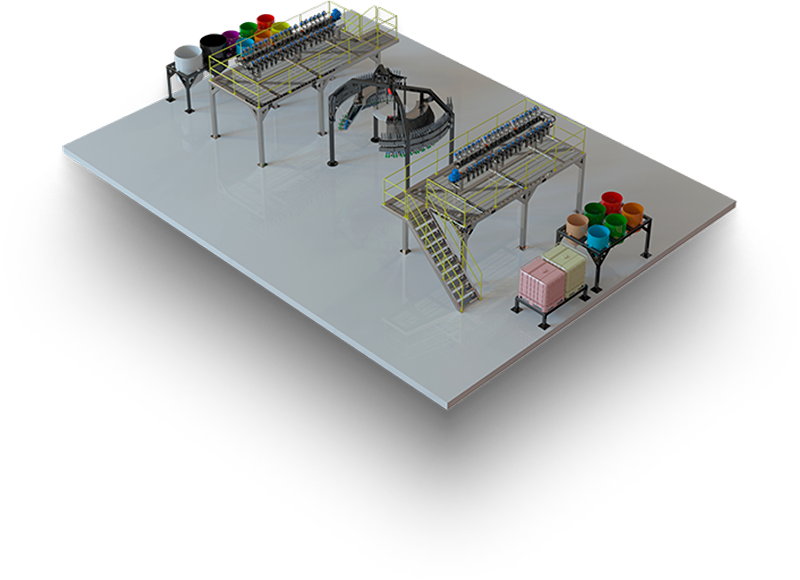

The SMART DISPENSING MACHINE is an innovative solution for the paint industry that combines high productivity, automation, cost reduction, and precision.

It is the market’s first Smart Dispensing Machine with a patented system for individual self-calibration of dosing pumps, 100% automated and operator-free.

This exclusive technology ensures precision and reliability to the system, even in challenging conditions.

HIGH PRODUCTIVITY

Revolutionizing dosing technology, our highly productive volumetric system matches the precision and reproducibility standards set by gravimetric dosing systems.

AUTOMATION

A 100% automated system for dosing pump calibration, which can be conducted outside of production hours, pre-programmed, and without the supervision of operators.

COST REDUCTION

Through the integration of a transmission shaft and a single motor, this system achieves simultaneous control of all pumps, providing a cost-efficient implementation approach.

EXCLUSIVE

The market´s first Smart Dispensing Machine with a patented system of individual self-calibration for dosing pumps, 100% automated, and operator-independent.

Our patented equipment stands out with an advanced and 100% automated ‘in-line’ calibration system.

This unique system allows for quick and precise calibrations of each dosing pump, ensuring efficiency even during periods of machine inactivity.

RMA TECH´s SMART DISPENSING MACHINE innovates with an efficient in-line calibration system, utilizing ‘IN-LINE PROVERS’ for individual or simultaneous calibration of multiple dosing pumps.

This method accelerates the dosing system calibration and facilitates maintenance. Manufactured with durable stainless steel, the provers are easily assembled, optimizing maintenance and extending the durability of the pumps.

This technology stands out for it´s a revolutionary design, employing a single motor to drive up to 40 dosing pumps.

This innovative system ensures precise volumetric dosing and eliminates the risk of slippage, providing total control over the pumps. It’s unique approach makes the machine more competitive and effective, ideal for dosing various components.

RMA TECH´s SMART DISPENSING MACHINE introduces a new strategy of simultaneous and smooth dosing, minimizing errors and ensuring precision.

It incorporates an advanced vision system for dosage monitoring. Utilizing high-resolution cameras and digital image processing, it simplifies installation and reduces the need for additional sensors.

Thus, it enables monitoring of the entire process, providing traceability and detailed analysis of the performance of the dosing valves.

Increasing dosage precision, RMA TECH´s SMART DISPENSING MACHINE includes an automatic temperature compensation system for each component.

Its temperature sensors, combined with data on densities and expansion coefficients, automatically adjust the material based on temperature, minimizing errors and ensuring extremely precise dosing.

Up to 100 components serving various product lines (cleaners, bases, cutting agents, solvents, additives, etc).

The continuous painting concept by RMA TECH is cost-effective, aligning seamlessly with TRANSMICELL and the color´s analyzer/qualifier.

Corporate systems, ERP, and databases are comprehensive.